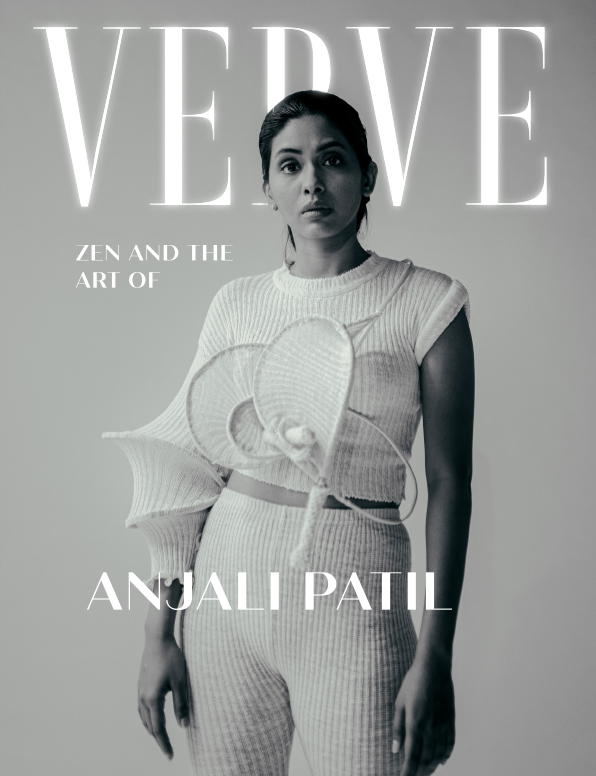

The Story of One of The World’s Premier Watchmakers

The girl is bent over in concentration, a magnifying eye glass strapped to her face…and when she looks up she takes a momentary glance at a candid photo of her family slipped into a metal wire stand. At another table, a man has a photo of the sunset staring at him, but if he were to look up, he would see, through large atelier windows, the lush green hillside on which the A. Lange & Söhne (pronounced ‘ah lang-eh’ and ‘zurn-neh’) manufactory resides, tucked away in the heart of Glashütte.

Germany’s prime watchmaking district, Glashütte (pronounced ‘glass-hoot-ey’), is an hour’s drive from the quaint Saxon town of Dresden and boasts 12 watch manufacturers of different calibres and hosts around 1,500 employees. These employees start their learning as early as the age of 15, and sometimes hail from different disciplines such as dentistry and porcelain making. They apply their fine motor skills expertise in watch manufacturing after undergoing at least three years’ training — including an extensive internal training — if they choose to work with A. Lange & Söhne. The people who work here are deeply passionate about what they do — their entire life revolves around their job.

The desks are pristine and clinical to a fault, except where you catch fragments of personalisation — a little bag of crisps or chocolate, kept neatly to the side — while the technicians work on tiny components with focus and sharp consistency, often not requiring the guidance of their computer screens that flash the exact technical procedure required at the time. The virtually dust-free and energy-efficient manufactory has individual ultra-modern workshops for the various processes — all the way from complications to engraving, from quality control to finishing and assembly. It takes a few minutes to a few hours to look over a single minutiae element; challenging ones can take up to a few days. The entire process of making a single handcrafted timepiece takes from six months to a year. It takes a person with a particular steadfast temperament and a great deal of passion for the job to have the staying power to continue in this vein.

And you can sense that as you walk through the spanking new manufactory that boasts a production area of 5,400 square metres, which can now house bigger and heavier machines, all entirely state of the art. You’re feeling like part of the establishment, clad in a crisp A. Lange & Söhne facility jacket and with machine-dispensed disposable plastic ‘socks’ on your shoe-covered feet. The double-skin walk-in facade has a climate-control function. Inaugurated last August, the facility, that cost in the double-digit tune of millions of euros, sees Saxony’s largest geothermal energy plant keeping the indoor climate pleasant year round. There is a serenity pervading the corridors and workstations, save for the sound of workmen putting the finishing touches to the new building. It is in this calm that perfection is allowed to thrive: an attention to detail, a rejection of that which doesn’t match their exacting standards.

Ferdinand Adolph Lange was the son of a gunsmith. The fire burnt strong in his belly for watchmaking, though, and in 1845 he managed to convince the local government to lend their support. He started in a small house on the Glashütte main street with a few apprentices. What had so far been a mining town was now poised to become the local centre of watchmaking. (His pocket watches remain highly coveted among collectors all over the world.) Despite managing to survive both world wars, he faced hard times in the 1850s and ’60s; and when, after the Second World War, East Germany came under the purview of the Russians, he continued manufacturing, though the A. Lange & Söhne name nearly disappeared into oblivion.

In 1990, F. A. Lange’s great-grandson, Walter Lange, took it upon himself to relaunch the brand. In 1994, their first collection was launched in Dresden Castle. He was recently bestowed with the Order of Merit of the Federal Republic of Germany (First Class) by German President Joachim Gauck in recognition of his services in re-establishing Saxony’s watchmaking industry. Two months after winning the award, he remains affable, charming and humble as he walks with us around the A. Lange & Söhne booth at the exclusive Salon International de la Haute Horlogerie (SIHH) watch fair in Geneva, talking appreciatively about Indian women and their outfits.

In just over 20 years, A. Lange & Söhne has developed 51 manufacture calibres, which has given them a prime position among the world’s finest watch brands. Their greatest successes include innovative timekeeping instruments such as the Lange 1 (with the first outsize date in a series-produced wristwatch) and the Zeitwerk (with its supremely legible, precisely jumping numerals). The jocular head of development, Anthony de Haas, identifies what has become key to most heritage watchmakers. “It’s very important for us as a brand to stay true to the identity we started with in the 1990s when we rebuilt the company. And it is a challenge to create something new with the A. Lange & Söhne identity that’s very recognisable. The Zeitwerk is a very good example of that — of pushing the limits, not only technically but also in design.”

Their showstopper Zeitwerk timepiece was launched in 2009. It hails from a German word, which means ‘time-movement’. Standing in the Zeitwerk workshop in Dresden, I am privy to the fact that the timepiece has 415 to 428 parts and 200 oiling points (with four different oils). Missing a single oiling point would lead to the watch potentially stopping — which leaves one thankful for the extensive quality control and assembly checks. The manufactory’s complication department is the vanguard of the brand’s prestige watches. The watchmakers who work there are responsible for a single timepiece from beginning to end (unlike the other watches that move from one specialised department to another). In a world where there is a heavy dependence on technology, it is astonishing to discover that in this case, machines are used for checking and not for making that change, as machines cannot make fine adjustments, like to the 100th of a millimetre!

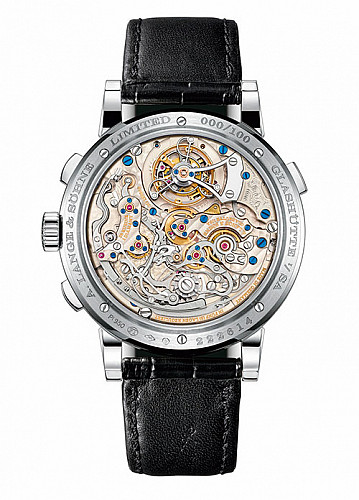

Last year, the big noise was the minute repeater with the decimal; this year at SIHH, the talking point was the limited-edition (100 pieces) Richard Lange Jumping Seconds which has an integrated jumping mechanism that makes it possible to display the time in strict one-second intervals. Says de Haas, “This is a typical collector’s watch — and you need a bit of an understanding of what’s going on. It’s a technical highlight, but packed in a very elegant, discreet way. You can make complications but they need to be nice-looking and fit the identity of the brand. Don’t do crazy things. Don’t start making diving or pilot watches, because others can do it far better.

A. Lange & Söhne never made watches to swim with, because the brand didn’t exist during the period when that became important. Also, with such a beautiful movement, with the sapphire case back, would I ever dare to jump in the water — even if I know it’s waterproof?”

A. Lange & Söhne has a tradition (started 150 years ago) of using German silver for their plates and movements, which requires two assemblies because of the delicacy of the metal. Despite the challenges associated with using this particular metal — not just limited to temperature and its sensitivity to humidity — it remains a speciality of the watchmaker for its beautiful golden, shining surface. It’s also symbolic of how the brand considers challenges and an indication of why it has so many movements to its name.

The watchmakers design their own tools for the intricate work. And it is intricate — as I soon realise when I am (as a surprise) taken to my own little private engraving workshop, where I am to sketch a design, then pick up a tool and work on a metal plate (which have both been made idiot-proof for newbies). I discover under local guidance that I am not entirely unforgivable at it, and I pass muster!

I get the hand-engraved piece returned to me in a box as a keepsake of the experience, which is nothing like the beautiful trademark floral engraving from Ferdinand Adolph Lange’s original pocket watches. Today, A. Lange & Söhne engravers undertake bespoke designs not just inside with specific creatives (like that of a royal family emblem, a motif or even a lover’s face) and initials, but also on the solid case back. You can place the bespoke order via your local boutique for a new piece and it then goes into the production process; while engraving initials on the balance cock can be done after purchase.

I walk over to the historic family building from 1873 (which once also housed production areas) and sit down for a light lunch with the director of press and public relations, Arnd Einhorn, who is eloquent about communicating the brand’s philosophy. There is a common speak and sensibility that pervades the brand and all associated personnel. De Haas (who incidentally had a stint at IWC before his 11 years at A. Lange & Söhne) was recently asked about making pilot’s watches. His response was simple and frank. ‘The Second World War for the Germans is a very black, dark period. Secondly, if we have companies like IWC who are masters in making a pilot’s watch, why should we do it, especially this year (the anniversary of the pilot’s watch)? To earn more money? To get more of their share of the market? That is not A. Lange & Söhne. We don’t decide on a market and then develop a product. We carefully develop the product families. And the marketing is merely our product, with the right information, with the right story.’

The developers and craftsmen in the valley who live in this placid, pristine environment, cut off from the machinations of the outside world, speaking only the local language, are the ones creating products for discerning people world over. The CEO, Wilhelm Schmid, is right when he says, “There is a certain German matter-of-factness, which can be perceived immediately.” De Haas identifies the quiet understatedness of the brand and the products as being influenced by the local area. “We are not so shiny, while we are fun. It’s very discreet; people are down to earth…with passion for detail. And I think that reflects in our products. We don’t come with pilots and spitfires and catwalks and Nicole Kidmans…it’s just us. And there are people who find it very boring, but we are how we are.” And he’s right. There is an atmosphere, in those quiet Glashütte hills filled with the sound of dedication.

The manufactory visit brings you closer to the heroes of these precision timepieces, affording you insight into a brand that believes in being subtly superior. The emotional connect isn’t with a clever marketing pitch, it’s with a labour-of-love marker of time.

A. Lange & Söhne consciously avoids having brand ambassadors — the watchmaker is the hero….as is the product.

5 things CEO Wilhelm Schmid wants you to know:

“Our first priority is that every new model is predestined to stand the test of time. This may lead to a classic design like the 1815 or more avant-garde concepts like the ZEITWERK Luminous.”

“Our second priority is recognition value. Even without the distinctive arched logo, an A. Lange & Söhne can always be identified. This is due to a combination of subtle features like the curvature of the lugs, the shape of the hands and the engraved look of the typography.”

“Our customers are quality-conscious watch connoisseurs, self-confident personalities who are seeking outstanding timepieces that reflect their individual style.”

“I am pleased to see that more and more women invest in our timepieces because they combine the best of two worlds: handcrafted mechanical excellence and timeless elegance. The majority of our watches are not designed for a specific gender but with a horological issue in mind.”

“Ever since we entered the Indian market in 2007, our timepieces have enjoyed growing popularity. We have, therefore, recently opened our fifth point of sale in Bengaluru.”

Anthony De Haas,

Head of Development

“Money talks, wealth whispers. Our watches are for whom wealth whispers. You are not buying an A. Lange & Söhne watch if you want to show off — when you buy a manually wound two-hand watch for 20,000 euros, you need to be a connoisseur. It’s very understated. Our sale of platinum watches is very high…why? They look like steel. So nobody recognises that you are wearing a watch that is worth 20-, 30- or 50,000 euros. But you have it for your own self. You know the inner value. Not merely the dial. The story is complete.”

Related posts from Verve:

Verve Trending

Sorry. No data so far.

us on Facebook to stay updated with the latest trends